Outline

Base oils are essential components in the production of lubricating greases, motor oils, and metalworking fluids. Each application requires specific oil compositions and properties to meet performance standards.

Virgin and Recycled Base Oils

Base oil can be produced in two primary ways:

- Virgin Base Oil: Derived from the refining of crude oil.

- Recycled Base Oil: Obtained through chemical treatment and refining of used engine oils.

At Al Jabal Group, we supply both Virgin Base Oil and Recycled Base Oil.

Virgin Base Oil

We offer Group I Virgin Base Oils in the following grades:

- SN 150

| Color (Max) | Pour Point (°C) | Flash Point (°C, COC) | Viscosity Index | Viscosity @ 100°C (cSt) | Appearance | Specification |

|---|---|---|---|---|---|---|

| ASTM D1500 | ASTM D97 | ASTM D92 | ASTM D2270 | ASTM D445 | Sight/Melt | Method |

| 1.5 | -12 | 208 | 95 | 5.4 – 7 | Bright / Clear | SN-150 |

- SN 350

| Test | Method | Unit | Result |

|---|---|---|---|

| Color | ASTM D 1500-R2017 | – | L1.5 |

| Flash Point | ASTM D 92-18 | °C | 224 |

| Density @ 15 °C | ASTM D 4052-18a | Kg/L | 0.8698 |

| Kinematic Viscosity @ 40 °C | ASTM D 445-21e1 | cSt | 47.36 |

| Kinematic Viscosity @ 100 °C | ASTM D 445-21e1 | cSt | 7.3 |

| Viscosity Index | ASTM D 2270 | – | 115.228 |

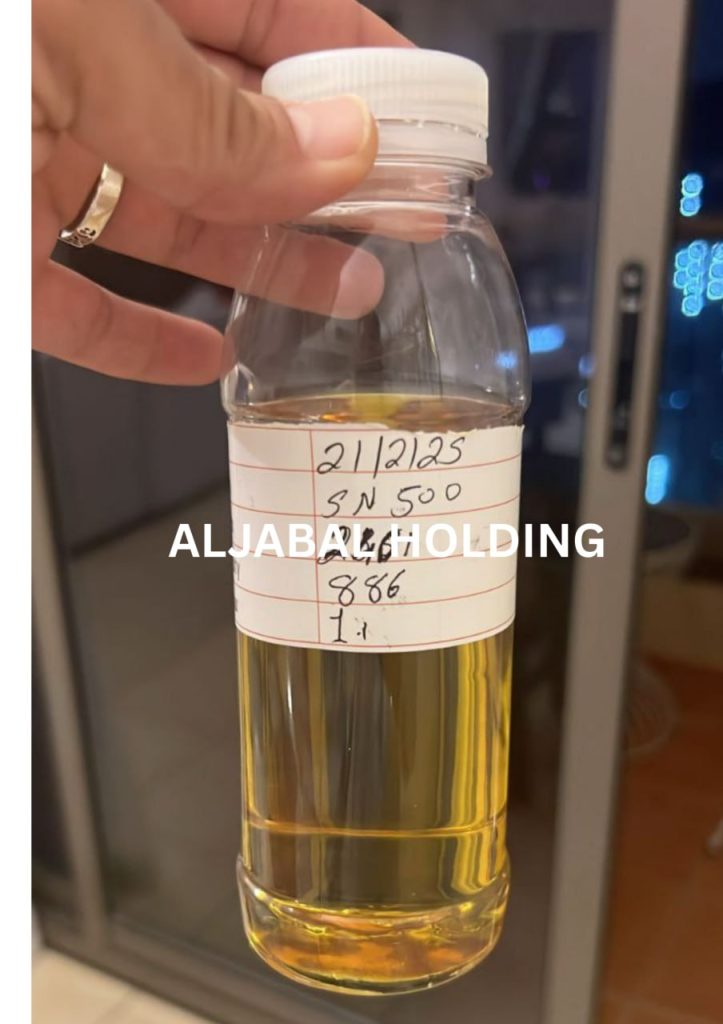

- SN 500

| Sr. No | Physical & Chemical Properties | ASTM Method | Unit | Result |

|---|---|---|---|---|

| 1 | Appearance | Visual | N.A | Bright & Clear |

| 2 | Color | D1500 | N.A | 2.0 |

| 3 | Kinematic Viscosity @ 40°C | D445 | cSt | 100.01 |

| 4 | Kinematic Viscosity @ 100°C | D445 | cSt | 10.95 |

| 5 | Viscosity Index | D2270 | N.A | 92 |

| 6 | Flash Point | D92 | °C | 244 |

| 7 | Pour Point | D97 | °C | -3 |

| 8 | Density @ 15°C | D4052 | g/cm³ | 0.8901 |

These products are available in bulk or drums based on customer requirements.

Recycled Base Oil

We produce recycled base oil using two distinct methods:

- Acid-Clay Treatment (Acid Technology)

- Distillation (Non-Acid Technology)

Acid-Clay Treated Recycled Base Oil

This process uses acid and clay to remove contaminants and impurities from used oil. Additional methods like hydrogenation and solvent extraction can also be applied. The final product is filtered, resulting in recycled base oils of the following grades:

- SN 150

| Physical Characteristics | Typical Values | Test Method |

|---|---|---|

| Density | 0.870 – 0.880 | ASTM D 1298 |

| Viscosity at 100°C (cSt) | 7 – 8 | ASTM D 445 |

| Flash Point (°C) | Min 190 | ASTM D 92 |

| Appearance & Color | 2 | ASTM D 1500 |

| Pour Point (°C) | – | ASTM D 97 |

- SN 350

| Physical Characteristics | Typical Values | Test Method |

|---|---|---|

| Density | 0.870 – 0.880 | ASTM D 1298 |

| Viscosity at 100°C (cSt) | 8.5 – 9.5 | ASTM D 445 |

| Flash Point (°C) | Min 210 | ASTM D 92 |

| Appearance & Color | Max 2 | ASTM D 1500 |

| Pour Point (°C) | 0 | ASTM D 97 |

- SN 500

| Physical Characteristics | Typical Values | Test Method |

|---|---|---|

| Density | 0.870 – 0.880 | ASTM D 1298 |

| Viscosity at 100°C (cSt) | 9 – 10 | ASTM D 445 |

| Flash Point (°C) | Min 230 | ASTM D 92 |

| Appearance & Color | Max 2 | ASTM D 1500 |

| Pour Point (°C) | 0 | ASTM D 97 |

Distilled Recycled Base Oil

Our distilled recycled base oil complies with international standards set by the American Petroleum Institute (API) and the International Lubricant Standardization and Approval Committee (ILSAC).

| Physical Characteristics | Test Method | SN150 | SN350 | SN500 |

|---|---|---|---|---|

| Density (g/cm³) | ASTM D-1298 | 0.870 – 0.885 | 0.870 – 0.885 | 0.880 – 0.890 |

| Viscosity at 100°C (cSt) | ASTM D-445 | 4.5 – 5.5 | 7 – 8 | 8 – 9.5 |

| Flash Point (°C) | ASTM D-92 | Min 190 | Min 220 | Min 240 |

| Appearance & Color | ASTM D-1500 | Clear 2 ± 0.5 | Clear 2 ± 0.5 | Clear 2 ± 0.5 |

| Viscosity Index | ASTM D-2270 | Min 90 | Min 90 | Min 90 |

| Pour Point (°C) | ASTM D-97 | Max -3 | Max -3 | Max -3 |

Properties of Distilled Recycled Base Oil:

- High viscosity index

- Excellent thermal stability

- Low volatility

Benefits of Distilled Recycling Method:

- Environmental Impact: Reduces pollution and promotes sustainable practices.

- Resource Conservation: Saves natural crude oil by reusing existing oil.

- Cost Efficiency: Offers a more economical alternative to virgin oil.

- Quality Assurance: Meets industry specifications for a wide range of uses.

- Energy Efficiency: Enhances machinery performance and reduces energy consumption.

We supply recycled base oils in grades SN 150, SN 350, and SN 500.

Lubricants

We supply a variety of lubricants for industrial, automotive, and marine use. Our range includes:

- Hydraulic brake fluids

- Automotive radiator coolants

- Lubricants for marine and industrial machinery

Let us know your specific lubricant requirements, and we will provide the relevant specifications and packaging options.

Slack Wax & Paraffin Wax

We supply Slack Wax in varying oil content from 5% to 30%, available in both drum and jumbo packaging formats, depending on customer preference. Slack wax can be provided in snow white or yellow appearance based on request.

Our Paraffin Wax is ideal for industries such as:

- Cosmetics

- Medical

- Food

- Candle manufacturing

Available grades:

- 1–3% oil content

- 3–5% oil content

- 5–8% oil content

Packaging: Cartons, each containing 6 wax slabs.

Paraffin Wax

| Property | Paraffin Wax 3-5% | Paraffin Wax 1-3% |

|---|---|---|

| Paraffin Wax Type | Macro Crystalline | Micro Crystalline |

| Production Capacity | 1000+ Ton | 500+ Ton |

| Delivery Time | 14 Days | 21 Days |

| Brand | KST Kimia Shargh Tolue | — |

| Oil Content | 3-5% | 1-3% |

| Flash Point | min 245°C | min 225°C |

| Melting Point | 60-65°C | 56-60°C |

| Kinematic Viscosity @100°C | 6-6.5 | 5.50 |

| Color | White or Yellow | White |

| Specific Gravity @25°C | 0.8-0.84G | 0.8-0.84G |

Rubber Process Oil (RPO)

Rubber Process Oil is a highly aromatic by-product from the solvent extraction process. It enhances vulcanization and lowers production costs for rubber products.

| No. | Test Name | Result | Test Method |

|---|---|---|---|

| 1 | Kin. Viscosity @40°C – cSt | 86.78 | ASTM D445 |

| 2 | Kin. Viscosity @100°C – cSt | 8.89 | ASTM D445 |

| 3 | Viscosity Index | 67 | ASTM D2270 |

| 4 | Density – Kg/m³ @15°C | 931 | ASTM D4052 |

| 5 | Pour Point – °C | +9 | ASTM D97 |

| 6 | Flash Point (Open Cup) – °C | 216 | ASTM D92 |

| 7 | Noack | 9.22 | ASTM D5800 |

| 8 | TAN – mg KOH/g | 0.13 | ASTM D974 |

| 9 | Gross Water Content | negative | Crackle Test |

| 10 | Color | >8.0 | ASTM D1500 |

| 11 | Ash – wt% | 0.007 | ASTM D482 |

| 12 | Sulfur – wt% | 3.51 % | ASTM D4294 |

We offer:

- Heavy Grade RPO

- Light Grade RPO

Due to increasing global demand, Al Jabal Group has expanded its capabilities in RPO trading and supply. With experienced RPO traders, we manage the procurement and global distribution efficiently, ensuring a robust supply chain from source to destination.

Vaseline (Petroleum Jelly)

Al Jabal Group also offers Vaseline, also known as Petroleum Jelly, available in various industrial, cosmetic, and medical grades.

Applications of Petroleum Jelly:

- As a lotion and ointment for hands and lips

- Prevention and treatment of nail fungus

- Relief for itchy or dry skin

- Treatment for nasal bleeding

- As a sunscreen base or daily moisturizer

- Hair care and dandruff treatment

- Enhancing natural skin tone and color

- Body and skin care moisturizer

Our petroleum jelly products meet diverse industry needs and are available in customizable packaging upon request.

Petroleum Jelly

| Test | Value | Test Method |

|---|---|---|

| Color (Lovibond) cell 1” | 1 – 1.5 | IP 17 |

| Specific Gravity @ 25°C | 0.79 – 0.84 | ASTM D1298 |

| Viscosity @ 100°C (cSt) | 4.4 – 5 | ASTM D445 |

| Congealing point (°C) | 48 – 50 | ASTM D938 |

| Drop melting point (°C) | 54 – 59 | ASTM D127 |

| Penetration 0.1 mm @ 25°C | 110 – 150 | ASTM D937 |

| Flash point (°C) | Min 200 | ASTM D92 |

| Acidity & Alkalinity | Passed | BP 2020 |

White Petroleum Jelly

| Test | Value | Test Method |

|---|---|---|

| Color (Lovibond) cell 1” | 0.7 – 1 | IP 17 |

| Specific Gravity @ 25°C | 0.79 – 0.84 | ASTM D1298 |

| Viscosity @ 100°C (cSt) | 4.4 – 6 | ASTM D445 |

| Congealing point (°C) | 48 – 53 | ASTM D938 |

| Drop melting point (°C) | 54 – 62 | ASTM D127 |

| Penetration 0.1 mm @ 25°C | 110 – 150 | ASTM D937 |

| Flash point (°C) | Min 200 | ASTM D92 |

| Acidity & Alkalinity | Passed | BP 2020 |

Snow White Petroleum Jelly

| Test | Value | Test Method |

|---|---|---|

| Color (Lovibond) cell 1” | 0.5 – 0.7 | IP 17 |

| Specific Gravity @ 25°C | 0.79 – 0.84 | ASTM D1298 |

| Viscosity @ 100°C (cSt) | 4.4 – 5 | ASTM D445 |

| Congealing point (°C) | 48 – 52 | ASTM D938 |

| Drop melting point (°C) | 54 – 60 | ASTM D127 |

| Penetration 0.1 mm @ 25°C | 115 – 140 | ASTM D937 |

| Flash point (°C) | Min 200 | ASTM D92 |

| Acidity & Alkalinity | Passed | BP 2020 |

Super Snow White Petroleum Jelly

| Test | Value | Test Method |

|---|---|---|

| Color (Lovibond) cell 1” | 0.1 – 0.3 | IP 17 |

| Specific Gravity @ 25°C | 0.79 – 0.84 | ASTM D1298 |

| Viscosity @ 100°C (cSt) | 4.5 – 6 | ASTM D445 |

| Congealing point (°C) | 50 – 56 | ASTM D938 |

| Drop melting point (°C) | 56 – 62 | ASTM D127 |

| Penetration 0.1 mm @ 25°C | 110 – 150 | ASTM D937 |

| Flash point (°C) | Min 200 | ASTM D92 |

| Acidity & Alkalinity | Passed | BP 2020 |

Lemon Petroleum Jelly

| Test | Value | Test Method |

|---|---|---|

| Flash point (°C) | Min 200 | ASTM D92 |

| Viscosity @ 100°C (cSt) | 4.4 – 6 | ASTM D445 |

| Color (Lovibond) cell 1” | ≥2 | IP 17 |

| Congealing point (°C) | 48 – 53 | ASTM D938 |

| Drop melting point (°C) | 54 – 62 | ASTM D127 |

| Penetration 0.1 mm @ 25°C | 110 – 150 | ASTM D937 |

| Specific Gravity @ 25°C | 0.79 – 0.84 | ASTM D1298 |

| Acidity & Alkalinity | Passed | BP 2017 |

Diesel 10 PPM

Al Jabal Group is also equipped to supply Diesel 10 PPM sourced from leading producers such as ENOC, ADNOC, and Shell in the United Arab Emirates.

Applications & Supply Options:

- Ideal for local U.A.E. bunkering companies

- Available for export in Flexi Tanks or ISO Tanks upon request

Our diesel supply is suitable for both domestic use and international export, adhering to quality standards and flexible delivery methods.

ENOC and Shell 10 ppm Diesel

| Test | Method | Unit | Result |

|---|---|---|---|

| Colour | ASMT D 1500-R2017 | – | W. W |

| Sulphur Content | ASMT D 4294-21 | ppm | 7 |

| Flash Point | ASMT D 93a-20 | °C | 86 |

| Density @ 15°C | ASMT D 1928-12Br17 | Kg/L | 0.829 |

| Density @ 29°C | ASMT D 1928-12Br17 | Kg/L | 0.819 |

| IBP | ASMT D 86-20b | °C | 208 |

| 10% Recovery | ASMT D 86-20b | °C | 252 |

| 20% Recovery | ASMT D 86-20b | °C | 265 |

| 30% Recovery | ASMT D 86-20b | °C | 275 |

| 40% Recovery | ASMT D 86-20b | °C | 283 |

| 50% Recovery | ASMT D 86-20b | °C | 291 |

| 60% Recovery | ASMT D 86-20b | °C | 300 |

| 70% Recovery | ASMT D 86-20b | °C | 309 |

| 80% Recovery | ASMT D 86-20b | °C | 320 |

| 85% Recovery | ASMT D 86-20b | °C | 327 |

| 90% Recovery | ASMT D 86-20b | °C | 336 |

| 95% Recovery | ASMT D 86-20b | °C | 349 |

| FBP | ASMT D 86-20b | °C | 355 |

| Recovery | ASMT D 86-20b | %vol | 97 |

| Residue | ASMT D 86-20b | %vol | 3 |

Adnoc and bapco 10 ppm Diesel

| Test | Method | Unit | Results |

|---|---|---|---|

| Color | ASTM D1500-24 | – | L 0.5 |

| Flash Point | ASTM D93-20 Proc.A | °C | 68 |

| Density @ 15°C | ASTM D4052-22 | Kg/l | 0.8356 |

| Kinematic, Viscosity@40°C | ASTM D445-24 | mm²/s | 3.575 |

| Water Content | ASTM D95-23 | % V/V | 0 |

| Sulphur Content | ASTM D4294-24 | mg/kg | 7 |

| Distillation (ASTM D86-23ae1) | |||

| IBP | ASTM D86-23ae1 | °C | 169 |

| 10% Vol Recovery | ASTM D86-23ae1 | °C | 235 |

| 50% Vol Recovery | ASTM D86-23ae1 | °C | 289 |

| 90% Vol Recovery | ASTM D86-23ae1 | °C | 343 |

| 95% Vol Recovery | ASTM D86-23ae1 | °C | 355 |

| FBP | ASTM D86-23ae1 | °C | 361 |

| Residue | % vol | 1.0 | |

| Loss | % vol | 1.0 |

See More Videos

Fuel oils

Fuel oils include heavy fuel oil (bunker fuel), marine fuel oil (MFO), furnace oil (FO), gas oil (gasoil), heating oils (such as home heating oil), diesel fuel, and others.

The term fuel oil generally includes any liquid fuel that is burned in a furnace or boiler to generate heat (heating oils), or used in an engine to generate power (as motor fuels). However, it does not usually include other liquid oils, such as those with a flash point of approximately 42 °C (108 °F), or oils burned in cotton- or wool-wick burners.

180 CST Fuel Oil

| Test | Method | Unit | ISO 8217:2024 | Result |

| Sulphur Content | ASTM D 4294-21 | % mass | – | 3.3914 |

| Flash Point | ASTM D 93b-20 | °C | Min 60 | 95 |

| Density @ 15 °C | ASTM D 4052-18a | Kg/L | Max 0.9910 | 0.9699 |

| Kinematic Viscosity 50 °C | ASTM D 445-21e1 | cSt | Max 180 | 157.81 |

| Water Content | ASTM D 95-13R18 | % vol | Max 0.50 | 0.10 |

| Ash Content | ASTM D 482-19 | % mass | Max 0.10 | 0.065 |

| Carbon Residue | ASTM D 189-06R19 | % wt | Max 15 | 10.18 |

| Total Sediment Potential | IP 390b | % m/m | Max 0.10 | TBA |

| Pour Point | ASTM D 97-17b | °C | Max 30 | +3 |

| Total Acid Number | ASTM D 974-14E2 | MgKOH/g | Max 2.5 | 0.78 |

| CCAI (Calculated Carbon Aromaticity Index) | ISO 8217:2017(E) | – | Max 860 | 841 |

| Calcium | IP 501 | mg/kg | Max 30 | 107 |

| Sodium | IP 501 | mg/kg | Max 100 | 69 |

| Aluminum + Silicon | IP 501 | mg/kg | Max 60 | 32 |

| Vanadium | IP 501 | mg/kg | Max 350 | 68 |

| Zinc | IP 501 | mg/kg | Max 15 | 5 |

| Phosphorus | IP 501 | mg/kg | Max 15 | 6 |

| Used Lubricating Oil (ULO) | – | – | – | – |

| Calcium and Zinc | IP 501 | mg/kg | Calcium >30 and Zinc >15 | 107 & 5 |

| Calcium and Phosphorus | IP 501 | mg/kg | Calcium >30 and Phosphorus >15 | 107 & 6 |

280 CST Fuel Oil

| Test | Unit | Specification | Test Method |

| Density @ 15DC | KG/M³ | MAX 970 | D-1298 |

| Kinematic Viscosity @ 50 DC | CST | MAX 280 | D-445 |

| Visco. Redwood1 @ 37.7DC | SECS | MAX 2500 | Calculated |

| Pour Point | DC | MAX 24 | D-97 |

| Flash Point | DC | MIN 65 | D-93 |

| Sulphur Total | WT% | MAX 3.5 | D-1552 |

| Carbon Residue (Conradson) | WT% | MAX 15 | D-189 |

| Ash | WT% | MAX 0.05 | D-482 |

| Water | VOL% | MAX 0.5 | D-1796 |

| Calorific Value (Higher) | MJ/KG | MIN 41.8 | Calculated |

380 CST Fuel Oil

| Test | Unit | Specification | Test Method |

| Density @ 15DC | KG/M³ | MAX 990 | D-1298 |

| Kinematic Viscosity @ 50 DC | CST | MAX 380 | D-445 |

| Pour Point | DC | MAX 32 | D-97 |

| Flash Point | DC | MIN 65 | D-93 |

| Sulphur Total | WT% | MAX 3.5 | D-1552 |

| Carbon Residue (Conradson) | WT% | MAX 15 | D-189 |

| Ash | WT% | MAX 0.15 | D-482 |

| Water | VOL% | MAX 1.0 | D-1796 |

| Calorific Value (Higher) | MJ/KG | MIN 41.7 | Calculated |