Recycled Base Oil Acidity: Advanced Processes and Industrial Methods for High-Quality Regeneration

Understanding the Acidity of Recycled Base Oil

Acidity in recycled base oil refers to the presence of acidic components resulting from oxidation, contamination, and degradation during its initial use. These acidic compounds, such as carboxylic acids, phenols, and other oxidized hydrocarbons, significantly reduce the oil’s lubricating properties and stability. Effective reduction of acidity is crucial to restoring the oil’s performance to near-virgin standards.

The acid number (AN), typically measured in mg KOH/g, provides an indicator of the oil’s degradation then must be addressed through advanced refining techniques.

Techniques for Reducing Acidity in Recycled Base Oil

1. Clay Treatment and Adsorption

We apply acid-activated clay to remove polar compounds and acidic contaminants. This process involves:

- Heating the recycled oil to 90–120°C.

- Mixing with 3–10% activated clay under continuous agitation.

- Vacuum filtration to separate the spent clay.

This step significantly reduces acidic components and color bodies.

2. Solvent Extraction

Solvent extraction is employed to remove oxygenated and acidic molecules selectively. We utilize solvents such as MEK (methyl ethyl ketone), furfural, or propane:

- Solvent is mixed with used oil in specific ratios (typically 1:1 to 2:1).

- The mixture is stirred at controlled temperatures (around 60°C).

- Phase separation occurs; the acidic compounds move to the extract phase.

This process achieves deeper purification compared to adsorption alone.

3. Hydrogenation and Hydrofinishing

Hydrogenation, or hydroprocessing, chemically stabilizes the base oil:

- Conducted in high-pressure reactors (100–200 bar).

- Temperature maintained at 300–400°C.

- In presence of Ni-Mo or Co-Mo catalysts.

Hydrogen reacts with unsaturated and oxygenated compounds, converting them into stable hydrocarbons, thus neutralizing acidity and improving oxidation resistance.

4. Acid-Clay Neutralization Process

A traditional but effective technique combining sulfuric acid and clay:

- 1–3% sulfuric acid is added to the oil to neutralize basic contaminants and precipitate heavy metals and acidic sludge.

- After acid treatment, the oil is treated with bleaching clay to absorb remaining polar molecules.

- Final filtration yields oil with substantially reduced total acid number (TAN).

While environmentally demanding, this method is cost-effective and still widely used in many regions.

5. Vacuum Distillation

Distillation under reduced pressure enables separation of base oil fractions without decomposition:

- Initial dehydration at 100–150°C.

- Distillation at 300–400°C under vacuum (5–10 mmHg).

- Heavy ends and acidic residues are left behind in the residue.

When integrated with clay treatment or hydrofinishing, this yields high-purity Group I and Group II base oils.

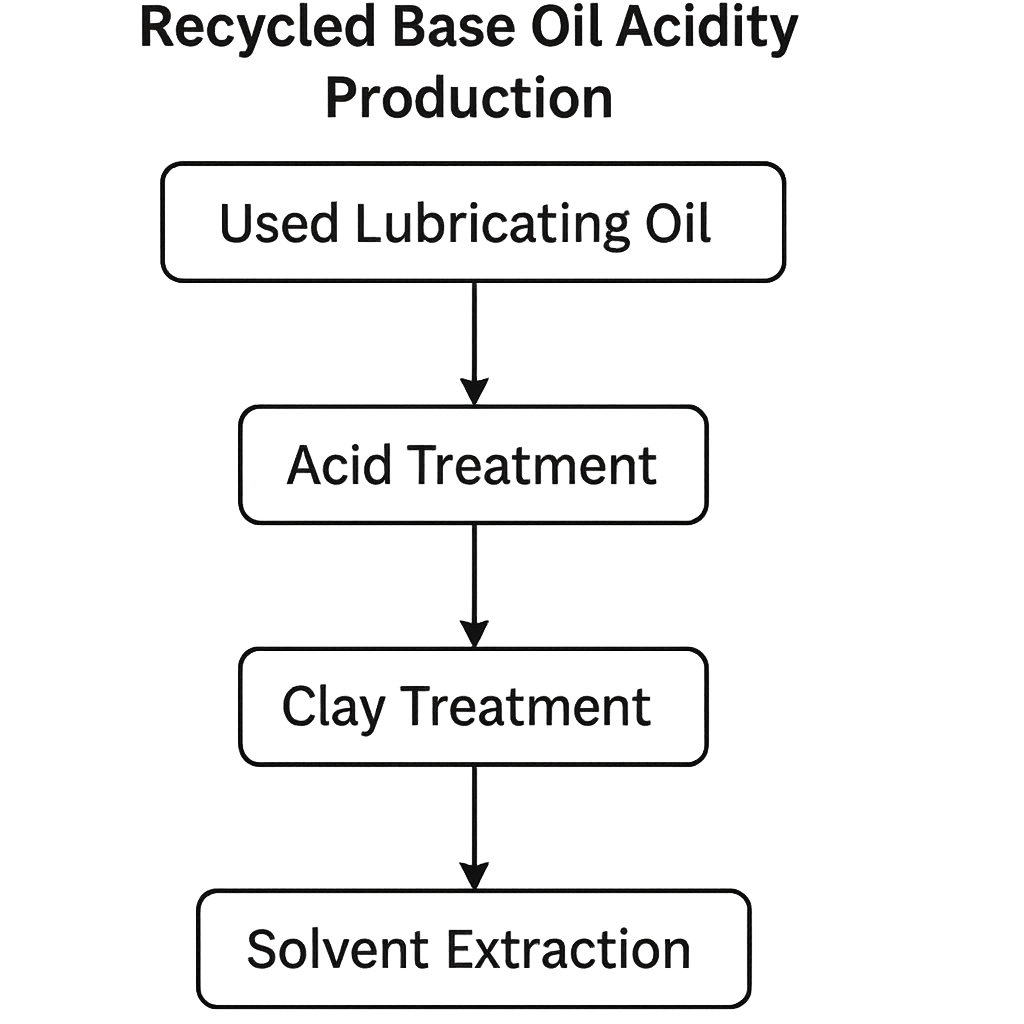

Recommended Flowchart: Recycled Base Oil Processing

Analytical Monitoring of Recycled Base Oil Acidity

We employ the following industry-standard methods to monitor and control acidity:

- ASTM D664 – Determination of acid number via potentiometric titration.

- FTIR Spectroscopy – Detection of carbonyl groups indicative of oxidation.

- GC-MS – For identifying residual polar and acidic molecules.

Routine quality control ensures that acid numbers remain below 0.05 mg KOH/g in high-grade regenerated base oils.

Industrial Applications of Low-Acidity Recycled Base Oil

The regenerated oils with minimized acidity are utilized in:

- Automotive lubricants

- Hydraulic and gear oils

- Industrial greases and processing oils

- Metalworking fluids

- Transformer and dielectric fluids

High purity and stability make them competitive with virgin base oils while offering sustainability benefits.

Environmental and Economic Benefits

- Waste Minimization: Reduces disposal of hazardous oil.

- Resource Conservation: Decreases demand for crude oil-derived virgin base oils.

- Cost-Effectiveness: Lower processing cost than refining virgin oil.

- Compliance: Meets global sustainability and circular economy standards.

Conclusion

Our multi-stage, precision-controlled processes ensure maximum acidity reduction and superior base oil recovery. Through innovative integration of clay treatment, solvent extraction, vacuum distillation, and hydrogenation, finally we produce eco-friendly, high-performance recycled base oils that meet stringent industrial requirements.