Advanced Recycled Base Oil via Distillation: Comprehensive Industrial Guide

Introduction to Recycled Base Oil and Its Industrial Importance

Recycling base oil through distillation is a critical process in waste oil management and sustainable industrial practices. As global demand for lubricants continues to rise, the significance of refining used oil into high-quality base oils grows exponentially. This method not only conserves natural resources but also mitigates environmental harm caused by improper disposal of waste oils.

What is Recycled Base Oil?

Recycled base oil is the refined product obtained after processing used lubricants through advanced re-refining techniques. Among these, vacuum distillation remains the most effective method for separating contaminants and restoring the oil’s original properties.

Types of Base Oil Obtained from Recycling

The following types of base oils can be recovered through re-refining:

- Group I Base Oil: Solvent-refined oils with basic performance properties.

- Group II Base Oil: Hydrotreated oils with higher purity and better oxidative stability.

- Group III Base Oil: Severely hydrocracked oils with near-synthetic characteristics.

- Group IV Base Oil: Polyalphaolefins (PAOs), not commonly obtained via recycling.

- Group V Base Oil: All other types including esters and bio-based oils.

Vacuum Distillation Process for Base Oil Recovery

Vacuum distillation is a high-efficiency separation technique that utilizes reduced pressure to lower the boiling point of oil fractions. This enables the recovery of base oils without cracking the molecular chains.

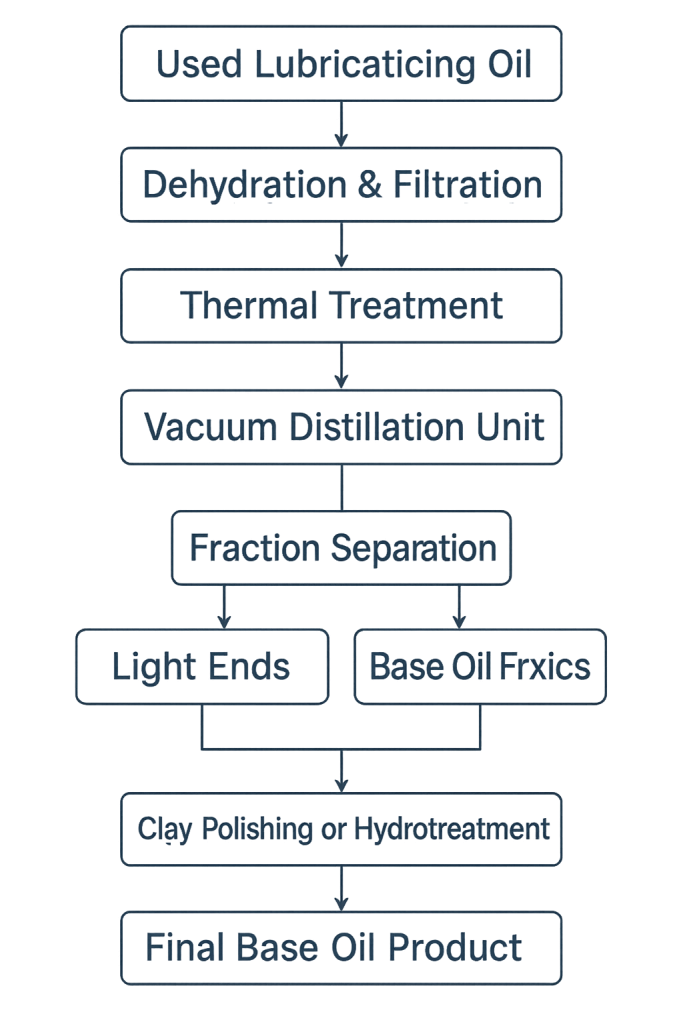

Key Steps in the Distillation Process:

- Pre-treatment: Removal of water, sludge, and heavy metals using dehydration and filtration.

- Thermal Cracking (if needed): Breakdown of high molecular weight compounds into manageable fractions.

- Vacuum Distillation: Separation of fractions under vacuum to prevent thermal degradation.

- Hydrotreatment or Clay Polishing: Enhancing the color, odor, and oxidation stability.

- Blending and Additive Addition: Tailoring the final product for specific applications.

Diagram: Process Flow of Base Oil Recycling

Benefits of Recycling Base Oil via Distillation

- Environmental Sustainability: Reduces soil and water contamination.

- Cost Efficiency: Lower production cost compared to refining crude oil.

- Energy Savings: Requires significantly less energy than crude oil refining.

- Regulatory Compliance: Meets strict environmental regulations in most countries.

Applications of Recycled Base Oil

Recycled base oils are widely used in the production of:

- Automotive and industrial lubricants

- Hydraulic fluids

- Metalworking fluids

- Transformer oils

- Rubber processing oils

Quality Standards and Certifications

Recycled base oils must adhere to international quality benchmarks, including:

- API Base Oil Classification

- ASTM D445 (Viscosity)

- ASTM D92 (Flash Point)

- ASTM D97 (Pour Point)

- TAN and TBN Measurements

These parameters ensure the oil meets functional and safety standards for reuse.

Challenges in the Recycling Process

- Contaminant Variability: Waste oils vary greatly in composition.

- Technology Requirements: Requires advanced distillation equipment and skilled personnel.

- Market Perception: Some sectors still perceive recycled oil as inferior despite evidence to the contrary.

How to Choose a Reliable Base Oil Recycling Supplier

When selecting a supplier or refinery partner for recycled base oils, consider:

- Proven track record in base oil recovery

- Use of high-quality vacuum distillation technology

- Compliance with environmental and safety regulations

- Certification in ISO, API, or other industry benchmarks

- Transparent product testing and analysis

Global Trends in Base Oil Re-refining

- Circular Economy Integration: More industries are adopting recycled oils for sustainability.

- Investment in Distillation Technology: Increase in capital flow towards distillation units.

- Government Incentives: Many countries offer tax benefits for oil recycling initiatives.

- Synthetic Oil Alternatives: Growing R&D into synthetic and semi-synthetic oils from recycled sources.

Conclusion

The recycling of base oil via distillation is a cornerstone of sustainable lubricant production. Through advanced vacuum distillation and refining processes, used oils can be transformed into high-grade base oils that rival virgin products in performance and reliability. As environmental concerns and resource constraints grow, the adoption of re-refined base oil will become an industry standard.