Introduction to the Bitumen Export Project

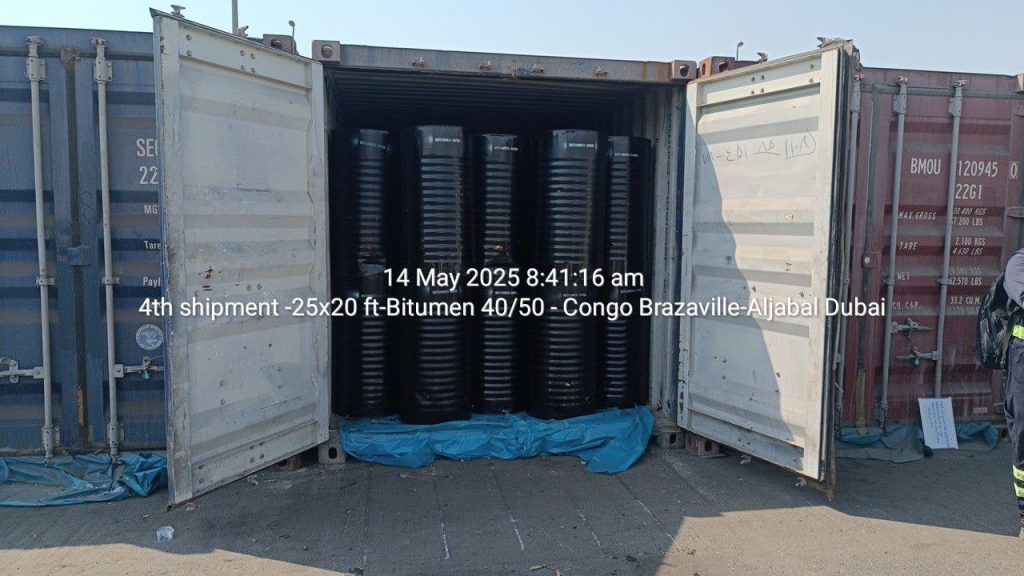

In May 2025, AlJabal Holding is gearing up for its fourth significant export of 25×20 ft containers filled with premium-grade Bitumen 40/50 to Brazzaville, Congo. This project isn’t just another shipment—it’s a testament to strategic expansion, commitment to quality, and a keen understanding of Africa’s growing infrastructure demands. Exporting high-quality road construction material like bitumen is a meticulous process, requiring logistical precision, regulatory compliance, and solid partnerships.

So, why is this export making headlines? Because it marks a critical point in regional infrastructure development and the cementing of long-term trade relationships between the Middle East and Central Africa. Brazzaville, Congo, a city teeming with development potential, is on the brink of massive road rehabilitation projects—and Bitumen 40/50 is the cornerstone of this transformation.

Let’s not forget, this isn’t a one-off. AlJabal Holding has been methodically building its reputation as a reliable exporter of road-grade materials. The May 2025 shipment, the fourth of its kind, reflects a growing demand from African nations for durable, climate-appropriate bitumen.

Overview of Bitumen 40/50

Bitumen 40/50 is a hard-grade penetration bitumen used predominantly for road construction in warmer climates. Its penetration value, measured in tenths of a millimeter, falls between 40 and 50—meaning it’s more viscous and suitable for areas that experience higher temperatures. This makes it ideal for countries like the Republic of Congo where road surfaces are exposed to intense sunlight and need to withstand heavy vehicular loads.

Bitumen 40/50 isn’t just any black, sticky substance. It’s engineered to perform under pressure—literally. The grading ensures that the product doesn’t soften excessively during hot days or crack under cooler conditions at night. In other words, it’s built to last.

Road engineers and infrastructure planners prefer this grade for high-traffic highways, major city roads, and export terminals. It offers superior bonding with aggregates and ensures long-lasting pavement life, reducing repair costs and increasing road safety.

Why Brazzaville, Congo?

Brazzaville is not only the capital of the Republic of Congo, but also a central hub for trade and construction. The city is currently undergoing a massive transformation with several road expansion and renovation projects aimed at improving traffic flow, enhancing logistics efficiency, and supporting economic growth.

Brazzaville’s location along the Congo River also makes it a key logistical route for both domestic and regional transport. Importantly, the government has prioritized infrastructure investments to connect rural and urban areas more efficiently. This focus on development creates a consistent demand for high-quality construction materials like Bitumen 40/50.

Moreover, AlJabal Holding’s growing partnership with local contractors and government authorities in Congo has paved the way for reliable, recurring shipments. The presence of a stable demand, coupled with favorable trade agreements, makes Brazzaville a strategic destination in the company’s African expansion strategy.

AlJabal Holding – The Export Powerhouse

AlJabal Holding has emerged as a powerhouse in the global export of construction and industrial materials. With a track record of timely, high-volume shipments, the company is a trusted name among contractors and governments across Africa, Asia, and the Middle East.

Founded on principles of quality, efficiency, and partnership, AlJabal Holding leverages its extensive logistics network and in-house technical expertise to fulfill large-scale orders with precision. The firm maintains a robust supply chain system, collaborating with top-tier shipping companies and port authorities to streamline every stage of the export process.

But AlJabal isn’t just about numbers. It’s about building relationships. Each shipment is the result of close coordination with local stakeholders, ensuring that the materials meet the destination’s specific climate and usage needs. The May 2025 bitumen export to Brazzaville is yet another example of how AlJabal Holding is playing a pivotal role in Africa’s infrastructure revolution.

Previous Successful Shipments

Before this fourth shipment, AlJabal Holding successfully completed three separate bitumen consignments to Brazzaville in the past year alone. Each of these shipments set new benchmarks for quality, efficiency, and customer satisfaction.

The first shipment was a pilot project aimed at testing the waters—literally and logistically. Once that proved successful, subsequent deliveries expanded in volume and complexity. Feedback from contractors praised the product quality and timely delivery, which helped avoid costly construction delays.

What sets AlJabal apart is their commitment to consistency. Each container undergoes rigorous quality checks, and documentation is processed well in advance to avoid hold-ups at customs. This attention to detail has turned AlJabal into a preferred supplier for many Central African infrastructure firms.

What is Bitumen 40/50?

Bitumen 40/50 is not just a number on a drum—it’s a carefully formulated material designed to meet the specific demands of high-traffic, high-temperature environments. As a penetration-grade bitumen, 40/50 indicates a hardness level where the needle penetration falls between 40 to 50 (in 1/10 mm units) under standardized conditions. This may sound technical, but in practical terms, it tells us how stiff or soft the bitumen is—making it an excellent fit for tropical and equatorial climates like that of the Republic of Congo.

This specific grade of bitumen is a petroleum-based hydrocarbon product obtained from the distillation of crude oil. It’s known for its binding properties and waterproof nature, making it the go-to material for road construction, airport runways, and even in some industrial waterproofing applications. What makes 40/50 stand out is its durability—it resists deformation under heavy loads and maintains its integrity over time, reducing the frequency and cost of repairs.

Beyond roads, Bitumen 40/50 finds its place in sealing and insulating foundations, waterproofing bridges, and even as a base component for certain industrial adhesives. It’s versatile, reliable, and above all, proven in harsh climate zones. For a rapidly developing region like Brazzaville, the quality and grade of the bitumen used will directly affect the longevity of the city’s infrastructure—and that’s where Bitumen 40/50 excels.

Significance of the Fourth Shipment

Now let’s talk about why the fourth shipment matters. You might think, “It’s just another batch, right?” Wrong. This is more than a routine delivery—it’s a strategic milestone. The fourth shipment not only reinforces AlJabal Holding’s operational capacity but also sends a strong signal to both current and potential partners that the company is here for the long run.

With every consecutive shipment, AlJabal has optimized its logistical workflows, improved packaging methods, and strengthened ties with port authorities and local distributors. These aren’t just administrative wins—they’re crucial steps toward market dominance in the Central African construction materials sector.

Moreover, the repetition of orders indicates trust and satisfaction from the receiving parties in Congo. Infrastructure projects are highly sensitive to supply reliability. Delays or inconsistent quality can throw off entire construction schedules. The fact that Brazzaville is on its fourth consignment suggests that previous deliveries have met, if not exceeded, expectations.

Additionally, this shipment allows AlJabal to scale its distribution networks. Larger orders mean bulk freight discounts, improved pricing for end clients, and a ripple effect of cost savings that make infrastructure projects more viable. Simply put, this fourth shipment is proof that the business relationship is thriving and scaling.

Shipment Details of the 4th Batch

Details matter—especially when you’re moving 25 containers of a highly valuable industrial material halfway across the globe. Each of the 25 containers involved in this May 2025 shipment measures 20 feet in length. These standard ISO containers are ideal for transporting bitumen because they ensure maximum efficiency in space utilization and cargo safety.

The containers are internally coated and thermally lined to protect the bitumen from moisture and extreme temperature fluctuations. Bitumen, particularly the 40/50 grade, requires careful temperature management during storage and transit. Any significant variation can affect its viscosity and overall performance on the road.

The shipment is scheduled for early May, giving enough buffer time to align with Congo’s dry season, which is the peak period for roadwork and construction activities. AlJabal Holding coordinates closely with port authorities, both at the origin and destination, to ensure timely loading, departure, and clearance.

Documentation is always prepared in advance. This includes bills of lading, certificates of origin, quality assurance certificates, and customs declarations. With pre-inspections conducted before container sealing, the chances of delay or rejection at Brazzaville’s customs are virtually eliminated.

Once the containers land at Pointe-Noire port—the main maritime entry for the Republic of Congo—they’re moved via inland freight to Brazzaville. AlJabal’s local partners handle this leg of the journey, ensuring seamless transition from sea to site. It’s a highly coordinated operation designed for efficiency and reliability.

The Role of Bitumen in Congo’s Development

Congo’s infrastructure growth is no secret. As urbanization accelerates and trade intensifies across the continent, the Republic of Congo has placed immense focus on road construction and maintenance. From connecting rural areas to upgrading intercity highways, bitumen plays a foundational role in this developmental story.

In Brazzaville alone, there are several government-backed and private sector-led projects aimed at road expansion and rehabilitation. Potholes, unpaved streets, and weather-worn highways have long been challenges. With Bitumen 40/50, the region can build roads that withstand both time and climate.

But it’s not just about roads. Improved transportation infrastructure has a domino effect—better roads mean faster logistics, more accessible healthcare, easier schooling for children in remote areas, and expanded economic zones. Bitumen becomes a catalyst for progress, not just a construction material.

By importing high-grade bitumen, Congo is investing in long-term infrastructure sustainability. The roads built today using this material could easily serve the nation for decades, provided they’re well maintained. This shift from quick fixes to lasting solutions marks a new chapter in the country’s infrastructure philosophy.

Shipping Logistics and Route

The journey of these 25 containers begins in the Gulf region—most likely from a port in the United Arab Emirates, where AlJabal Holding has a strong operational base. The containers are loaded onto bulk or containerized cargo vessels and travel along a defined maritime route passing through the Red Sea, around the Horn of Africa, and down the west coast toward Central Africa.

The key port of entry is Pointe-Noire, one of Congo’s most critical maritime terminals. It’s equipped to handle large volumes of containerized cargo and offers direct road connectivity to Brazzaville. After clearance, the containers are transported overland via flatbed trucks or container carriers to the city.

Navigating this route involves dealing with several logistical considerations—ranging from maritime weather conditions to regional piracy risks and international shipping regulations. AlJabal mitigates these risks by working with seasoned freight partners and using real-time tracking systems.

The company also prepares contingency plans for rerouting or warehousing in case of delays. With each shipment, the logistics chain becomes more refined, reducing transit times and optimizing costs. For the May 2025 delivery, AlJabal has already booked slots and coordinated with shipping agents to ensure a smooth voyage.

Regulatory Compliance and Documentation

When it comes to international trade, compliance is not optional—it’s everything. For AlJabal Holding, each bitumen shipment is backed by a rock-solid foundation of regulatory adherence. The fourth shipment to Brazzaville in May 2025 is no different. From export licenses to environmental documentation, every detail has been meticulously managed to ensure seamless transit and delivery.

Let’s break this down. First, export licenses are obtained from the origin country’s trade authorities. These licenses confirm that the material being shipped—Bitumen 40/50—is authorized for export under international trade laws and complies with both origin and destination regulations. Bitumen, being a petroleum derivative, often comes under controlled commodities due to safety and environmental considerations.

Next is the certificate of origin. This document verifies the country where the bitumen was manufactured and processed, an essential piece of paperwork that determines tariff obligations and eligibility under bilateral trade agreements. In this case, it ensures that Congo receives the bitumen at the agreed-upon duties or exemptions.

Environmental compliance is also a key pillar. Bitumen transportation, especially in bulk, must adhere to eco-safety protocols. This includes using sealed containers that prevent leakage and contamination. AlJabal Holding adheres strictly to these standards, often going above what’s required to build a strong reputation as a responsible exporter.

Safety data sheets (SDS) accompany every shipment, detailing the chemical composition, handling procedures, and emergency measures in case of spillage or fire. The receiving teams in Congo are trained in these protocols to maintain safety from the port to the construction site.

With all this documentation in place, customs clearance becomes a swift and efficient process. No back-and-forth. No hold-ups. Just a clean handover from port authorities to local distributors—exactly how efficient trade should be.

Market Analysis for Bitumen in Central Africa

Central Africa, led by nations like the Republic of Congo, Cameroon, and Gabon, is undergoing a construction boom. With increasing government spending on infrastructure, the demand for high-quality construction materials—especially bitumen—is surging. This fourth shipment by AlJabal Holding is perfectly timed to tap into that growing market.

In the last five years, the import volumes of penetration-grade bitumen like 40/50 have more than doubled in the region. Urban sprawl, highway developments, and international corridor projects are major drivers. Brazzaville, in particular, serves as a trade and logistics epicenter, meaning road quality is crucial for the movement of goods within and beyond the country.

But AlJabal isn’t operating in a vacuum. The Central African bitumen market is becoming increasingly competitive. Suppliers from Asia, the Middle East, and even local African producers are vying for a piece of the pie. However, what sets AlJabal apart is its consistency in product quality, dependable delivery timelines, and strategic partnerships within the region.

Their approach isn’t just to supply bitumen—but to become part of the region’s infrastructure fabric. That means not only delivering a product but offering technical support, tailored logistics, and responsive after-sales service. This integrated model makes AlJabal more than a vendor—it makes them a trusted partner in development.

Looking ahead, the market is expected to continue growing at a steady pace. Initiatives like the African Continental Free Trade Area (AfCFTA) will further open borders and streamline trade, making it easier for companies like AlJabal to expand their footprint. The May 2025 shipment is a key stepping stone in that broader vision.

Challenges Faced and Overcome

Let’s be real—international shipping isn’t without its hurdles. Weather, geopolitical issues, port congestion, and raw material fluctuations can all throw a wrench into even the best-laid plans. So how does AlJabal Holding handle these challenges? With preparation, flexibility, and a bit of old-fashioned grit.

One major challenge in exporting bitumen is maintaining its physical properties during long transits. Bitumen 40/50 is sensitive to temperature changes, and if not stored correctly, its viscosity can change—compromising its performance. To combat this, AlJabal uses insulated containers with thermal control, ensuring the product arrives in top condition.

Then there’s the issue of port delays. West African ports, while improving, are notorious for bureaucratic slowdowns and limited offloading capacity. That’s why AlJabal works directly with port authorities in Pointe-Noire, securing time slots and coordinating in advance to avoid peak traffic hours. They’ve also partnered with local logistics firms that know the terrain and can push paperwork through faster than international agents.

Currency fluctuations and inflation in both Congo and the exporting country can impact profit margins and pricing. AlJabal navigates this by locking in exchange rates ahead of time and building cost contingencies into their contracts, ensuring that clients aren’t hit with last-minute price hikes.

And finally—let’s talk COVID aftershocks. Global shipping still hasn’t fully recovered from the pandemic, and container shortages remain an issue. AlJabal mitigated this by reserving container space months in advance for the May 2025 shipment, sidestepping the global race for freight capacity.

Each challenge has made the team smarter and more agile. Lessons from earlier shipments have shaped a more robust supply chain model—one that can withstand turbulence and still deliver on time, every time.

Technology and Innovation in Bitumen Packaging

Gone are the days of using outdated drums and leaky barrels for transporting bitumen. AlJabal Holding embraces modern technology in every phase of its packaging and storage process, making sure that the product integrity is preserved from the moment it leaves the refinery to when it reaches the construction site in Brazzaville.

One of the standout innovations used by AlJabal is the adoption of bitu-containers—specialized insulated containers designed to hold hot bitumen during transit. These containers maintain the temperature between 140–160°C, preventing the bitumen from solidifying and ensuring easy unloading upon arrival. This not only saves time but also cuts down on energy costs at the receiving end.

Vacuum-sealing is another method the company employs to prevent oxidation—a common issue when bitumen is exposed to air over long periods. This keeps the chemical properties of Bitumen 40/50 stable, ensuring that the material performs as expected during application.

Each container is equipped with RFID tags and IoT sensors to monitor temperature, pressure, and handling conditions in real-time. This smart tracking system sends alerts to the logistics team in case of any anomalies, allowing them to take corrective measures instantly. It’s like having a digital guardian riding along with every shipment.

Additionally, AlJabal has invested in ergonomic drum designs for clients who prefer smaller packaging formats. These drums are leak-proof, stackable, and made of recyclable material, reinforcing the company’s commitment to safety and sustainability.

Sustainability Measures in the Export Process

Sustainability isn’t just a buzzword anymore—it’s a necessity. AlJabal Holding understands the importance of minimizing its environmental impact, especially when dealing with petroleum-based products like Bitumen 40/50. That’s why the company has integrated a wide range of eco-conscious practices into its entire export chain, from packaging and storage to transport and delivery.

One of the key areas of focus is reducing the carbon footprint associated with bitumen exports. AlJabal does this by optimizing shipping routes to reduce travel distances and fuel consumption. Instead of selecting carriers based purely on cost, the company chooses those that use modern, fuel-efficient vessels and adhere to international emission standards such as MARPOL regulations. These efforts cut down on CO₂ emissions during transit—a win for both business and the planet.

Recyclable and Reusable Packaging

The company also places strong emphasis on recyclable and reusable packaging. The insulated containers and drums used in the May 2025 shipment designed not only for single-use efficiency but also for long-term use across multiple shipping cycles. This circular packaging model greatly reduces waste and conserves resources.

AlJabal has also implemented a green warehousing strategy. Storage facilities at the port of origin are equipped with solar-powered systems, eco-friendly lighting, and advanced insulation to regulate temperature without excessive energy use. The company is working toward ISO 14001 certification—a globally recognized standard for environmental management systems.

Water conservation is another crucial factor. During the bitumen cooling process, AlJabal employs a closed-loop water system that recycles and reuses water, minimizing usage and preventing contamination. This approach ensures compliance with local and international environmental laws.

By integrating these sustainability measures, AlJabal Holding not only meets its regulatory obligations but also strengthens its brand as a forward-thinking, responsible exporter. Clients in Congo and beyond increasingly favor partners who align with global sustainability goals—and AlJabal is clearly leading by example.

Economic Impact of AlJabal Holding’s Bitumen Export

When AlJabal Holding ships 25×20 ft containers of Bitumen 40/50 to Brazzaville, it’s not just about roads—it’s about ripple effects. This export initiative contributes directly to local economies, job creation, and long-term infrastructure improvements, creating a chain reaction of economic activity across both the exporting and importing nations.

Let’s start with the Republic of Congo. Infrastructure development is one of the primary catalysts for economic growth. With the arrival of high-quality bitumen, local construction companies can execute roadworks faster, better, and more efficiently. This leads to better connectivity between cities and villages, which in turn promotes trade, tourism, and access to essential services like healthcare and education.

More jobs are created—both directly and indirectly. From customs clearance agents at Pointe-Noire port to the laborers laying asphalt on highways in Brazzaville, this bitumen shipment generates employment at every step. Then there are the ancillary services—transportation firms, fuel suppliers, equipment rentals—all benefiting from the increased construction activity.

On the exporting side, AlJabal Holding employs hundreds of workers in logistics, quality control, packaging, and documentation. The demand for materials like Bitumen 40/50 sustains refinery jobs and fuels the local transport sector in the Middle East. By fulfilling recurring contracts like the one with Congo, AlJabal ensures long-term job security for its team and stable income for its partners.

The economic benefits extend even further. With better infrastructure, regional integration becomes easier. Farmers can move produce to urban markets faster. Small businesses get better access to raw materials. Government revenues grow through improved commerce and tax collection. In essence, every container of bitumen is not just construction material—it’s a building block of economic transformation.

Future of Bitumen Trade in Central Africa

The future is bright for the bitumen trade in Central Africa, and AlJabal Holding is positioning itself to be at the center of it all. With major regional infrastructure projects already underway—like the Brazzaville-Kinshasa Bridge and the Trans-African Highway—demand for high-performance construction materials will only continue to rise.

One of the key trends driving this growth is regional collaboration. Through initiatives like the African Union’s Programme for Infrastructure Development in Africa (PIDA), countries are pooling resources to improve transportation networks. This translates into long-term demand for products like Bitumen 40/50 that offer durability, weather resistance, and economic value.

AlJabal Holding is already planning to scale operations. The company is evaluating partnerships for setting up local blending and distribution units in Africa, which would shorten delivery timelines and further reduce logistics costs. These localized facilities could also offer job training and technical workshops for African contractors, strengthening on-ground capabilities.

Digital transformation is also part of the future. AlJabal aims to implement AI-powered supply chain systems that forecast demand patterns, optimize inventory, and improve customer service. Smart contracts and blockchain documentation are on the horizon, promising faster and more secure trade transactions.

In short, the May 2025 shipment isn’t the end of a journey—it’s the beginning of a new chapter. With the infrastructure sector booming and technology evolving, the bitumen trade is set to thrive in Central Africa, and AlJabal Holding is ready to lead that charge.

Conclusion

AlJabal Holding’s fourth shipment of 25×20 ft containers of Bitumen 40/50 to Brazzaville in May 2025 is more than a logistical milestone—it’s a symbol of progress, partnership, and potential. From the strength of its product to the precision of its planning, every aspect of this operation reflects excellence. More importantly, it signifies how a single export can influence an entire region’s development.

By focusing on quality, sustainability, and long-term collaboration, AlJabal Holding isn’t just shipping materials—they’re paving the way for a better, more connected Africa. The roads built with this bitumen will carry people, goods, and dreams for years to come. That’s the real impact. And it all starts with 25 containers, a plan, and a vision.

FAQs

1. What is Bitumen 40/50 used for?

Bitumen 40/50 is primarily used for road construction in hot climates. It’s durable, heat-resistant, and provides strong bonding with aggregates, making it ideal for highways, city roads, and industrial applications.

2. Why is Brazzaville a strategic export destination?

Brazzaville is undergoing rapid infrastructure development, and its central location along the Congo River makes it a key logistics hub. Exporting bitumen here supports national road projects and boosts regional trade.

3. How does AlJabal Holding ensure quality and safety?

Each shipment is backed by rigorous quality checks, thermal-controlled packaging, and compliance with international safety standards. The company also uses real-time tracking and RFID technology for monitoring.

4. What makes this shipment different from previous ones?

This is the fourth and largest shipment to date, highlighting AlJabal’s growing footprint in Central Africa and reflecting improved logistics, deeper partnerships, and higher demand from the Congolese market.

5. Are there future shipments planned for 2025 and beyond?

Yes, AlJabal Holding is actively planning additional shipments and is exploring setting up local distribution centers in Africa to meet increasing demand and enhance service delivery.