Introduction

What is RC Base Oil?

If you’ve ever dived into the world of lubricants and industrial oils, you’ve probably heard terms like “Group I”, “Group II”, and “RC base oil.” But what exactly is RC base oil? Short for “Refined Crude,” RC base oil is a highly purified petroleum-based product used as a foundation for manufacturing high-performance lubricants. It’s the base ingredient that determines how your engine oil or industrial grease performs under pressure, heat, and friction.

RC base oil isn’t your everyday mineral oil—it’s engineered for better oxidation stability, higher viscosity index, and enhanced wear protection. And thanks to modern refining processes like Acid Technology, RC base oils now offer even better performance across a range of demanding applications.

So, when industries demand consistent, high-quality lubrication, RC base oil becomes the go-to choice. From automotive to aerospace, this versatile lubricant base ensures machines run smoother, cooler, and longer.

Why Acid Technology Matters in Base Oil Production?

Now, let’s talk tech. Acid Technology isn’t some gimmicky term—it’s a breakthrough in refining science. Traditionally, base oils were processed using solvent-based methods. While those methods work, they leave behind unwanted compounds like sulfur, wax, and aromatics. Acid Technology, on the other hand, uses advanced chemical treatments to strip away impurities at a molecular level, delivering ultra-pure base oil.

This refined process not only boosts the oil’s performance but also ensures it meets the stringent environmental and industrial standards of 2025. We’re talking about better thermal stability, lower volatility, and improved compatibility with modern engine additives.

In short, Acid Technology takes RC base oil from “good enough” to “best in class.” It’s the difference between a standard sedan and a high-performance race car—both will get you there, but one does it cleaner, faster, and more efficiently.

Overview of Aljabal Holding

Company Background and Industry Reputation

When it comes to sourcing RC base oil enhanced with Acid Technology, Aljabal Holding stands tall as a global leader. Founded with a vision to revolutionize the petroleum supply chain, Aljabal Holding has spent years refining not just oil—but also their operations, ethics, and customer relationships.

Operating across several continents, Aljabal Holding is known for its commitment to quality, innovation, and reliability. The company works closely with industrial giants, lubricant manufacturers, and energy firms, making it a trusted name in the world of advanced base oils.

With decades of expertise and a forward-thinking approach, Aljabal has positioned itself at the forefront of the base oil revolution.

Core Areas of Business

While RC base oil is their flagship offering, Aljabal Holding’s portfolio is anything but limited. The company also supplies:

- Group I, II, and III base oils

- Specialty solvents

- Additives for lubricant blending

- Industrial chemicals

- Fuel oil and diesel derivatives

Their diversified focus ensures they remain resilient in a fluctuating market while meeting the evolving needs of clients across sectors.

Commitment to Innovation and Sustainability

In a world where carbon footprints matter, Aljabal Holding is not just chasing profits—they’re chasing progress. Their investments in green technologies, sustainable sourcing, and waste reduction protocols prove their dedication to responsible business.

By incorporating Acid Technology, they’re not just enhancing oil—they’re minimizing environmental impact. Cleaner processes mean fewer emissions and a safer product lifecycle from start to finish.

This isn’t just corporate fluff either. Aljabal holds multiple certifications in quality management, environmental standards, and occupational safety—making them one of the most well-rounded suppliers in the industry.

Understanding RC Base Oil

What Does “RC” Stand For?

The term RC Base Oil may sound like industry jargon, but it’s actually quite straightforward. “RC” stands for Refined Crude, referring to base oils that have undergone extensive refining processes to remove impurities and enhance performance attributes. This isn’t the same crude oil that comes straight out of the ground—it’s been processed to deliver premium-quality lubrication properties suitable for demanding industrial and automotive applications.

RC base oil sits somewhere between traditional solvent-refined oils and fully synthetic bases. It’s not entirely synthetic, but it performs far better than untreated or lightly refined oils. The use of Acid Technology during the refining stage pushes the purity and stability of RC base oils to a new level.

So why the buzz around RC base oil in 2025? It’s all about meeting modern lubrication needs—from cleaner emissions and fuel efficiency to longer oil change intervals and enhanced machinery protection. And that’s exactly what RC base oil delivers.

Composition and Performance Characteristics

RC base oils are all about consistency, clarity, and cleanliness. Here’s what sets them apart composition-wise:

- Low sulfur content: Reduces deposits and corrosion in engines and machinery.

- High viscosity index (VI): Maintains consistent thickness across temperature changes.

- Excellent thermal and oxidative stability: Prevents sludge formation, even under high-stress operations.

- Superior solubility: Works seamlessly with additives for enhanced performance.

This makes RC base oils ideal for high-speed engines, heavy-duty industrial equipment, hydraulic systems, and even marine engines. In short, it’s the base oil of choice for those who don’t compromise on quality.

How RC Base Oil Differs from Other Types

Let’s compare RC base oil to traditional Group I and Group II oils:

| Feature | RC Base Oil | Group I Oil | Group II Oil |

|---|---|---|---|

| Refining Process | Acid Technology | Solvent Refining | Hydroprocessing |

| Sulfur Content | Very Low | High | Low |

| Oxidation Resistance | Excellent | Poor | Good |

| Compatibility with Additives | Very High | Moderate | High |

| Application Range | Broad (Automotive, Industrial, Marine) | Limited | Broad |

The difference is clear. RC base oil offers near-synthetic-level performance while remaining cost-effective, making it a popular choice for lubricant manufacturers around the globe.

Acid Technology in Base Oil Processing

What is Acid Technology?

Acid Technology represents a cutting-edge evolution in oil refining. It’s a chemical-based method where acid compounds are used to break down, extract, and purify crude oil at a molecular level. Unlike traditional processes that merely separate oil components, Acid Technology actively enhances the structure of the base oil.

Here’s how it works:

- Step 1: Crude oil is heated and exposed to controlled acidic agents.

- Step 2: Impurities like sulfur, nitrogen, and unsaturated hydrocarbons are chemically neutralized or removed.

- Step 3: The result is a cleaner, clearer, more stable base oil—ideal for blending into premium lubricants.

It’s not just about chemistry—it’s about creating a refined base that performs better, lasts longer, and reduces environmental strain.

Benefits of Using Acid Technology

Acid Technology isn’t just a buzzword—it brings real-world advantages to both manufacturers and end-users:

- Improved oil purity: Fewer contaminants mean better performance.

- Extended lubricant life: Longer intervals between oil changes.

- Enhanced oxidation resistance: Prevents sludge, varnish, and thermal degradation.

- Better additive compatibility: Ensures full benefit from anti-wear, detergent, and dispersant packages.

- Cost-effective alternative to full synthetics: Delivers near-synthetic performance at a lower cost.

For companies seeking high-quality lubricants without breaking the bank, acid-refined RC base oil is a no-brainer.

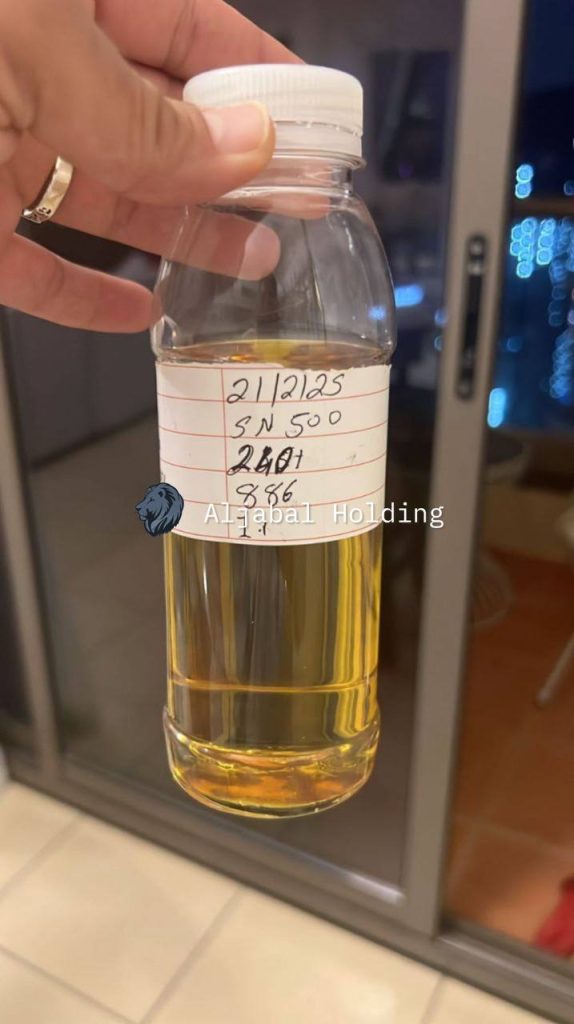

SN-500 Test Report

| Physical Characteristics | Typical Values | Test Method |

|---|---|---|

| Density | 0.870–0.880 | ASTM D 1298 |

| Viscosity at 100°C | 9–10 | ASTM D 445 |

| Flash Point | Min 230 | ASTM D 92 |

| Appearance & Color | Max 2 | ASTM D 1500 |

| Pour Point | 0 | ASTM D 97 |

SN-300 Test Report

| Physical Characteristics | Typical Values | Test Method |

|---|---|---|

| Density | 0.870–0.880 | ASTM D 1298 |

| Viscosity at 100°C | 8.5–9.5 | ASTM D 445 |

| Flash Point | Min 210 | ASTM D 92 |

| Appearance & Color | Max 2 | ASTM D 1500 |

| Pour Point | 0 | ASTM D 97 |

SN-150 Test Report

| Physical Characteristics | Typical Values | Test Method |

|---|---|---|

| Density | 0.870–0.880 | ASTM D 1298 |

| Viscosity at 100°C | 7–8 | ASTM D 445 |

| Flash Point | Min 190 | ASTM D 92 |

| Appearance & Color | 2 | ASTM D 1500 |

| Pour Point | – | ASTM D 97 |

Environmental Impact and Handling

One of the biggest challenges in oil refining is balancing performance with environmental responsibility. Acid Technology addresses this head-on by using controlled chemical reactions that produce minimal byproducts and waste. Many of the acids used are recyclable, and Aljabal Holding has implemented closed-loop systems that ensure waste acids are recovered and reused.

Additionally, acid-refined oils burn cleaner, releasing fewer hydrocarbons and harmful emissions when used in engines and machinery. This makes them ideal for markets with strict environmental regulations, including Europe, North America, and parts of Asia.

Safety-wise, Aljabal ensures all acid-handling is done in compliance with international standards like OSHA, ISO, and REACH. Proper storage, transport, and PPE (Personal Protective Equipment) protocols are followed to ensure both product quality and worker safety.

Aljabal Holding’s Role as a Leading RC Base Oil Supplier

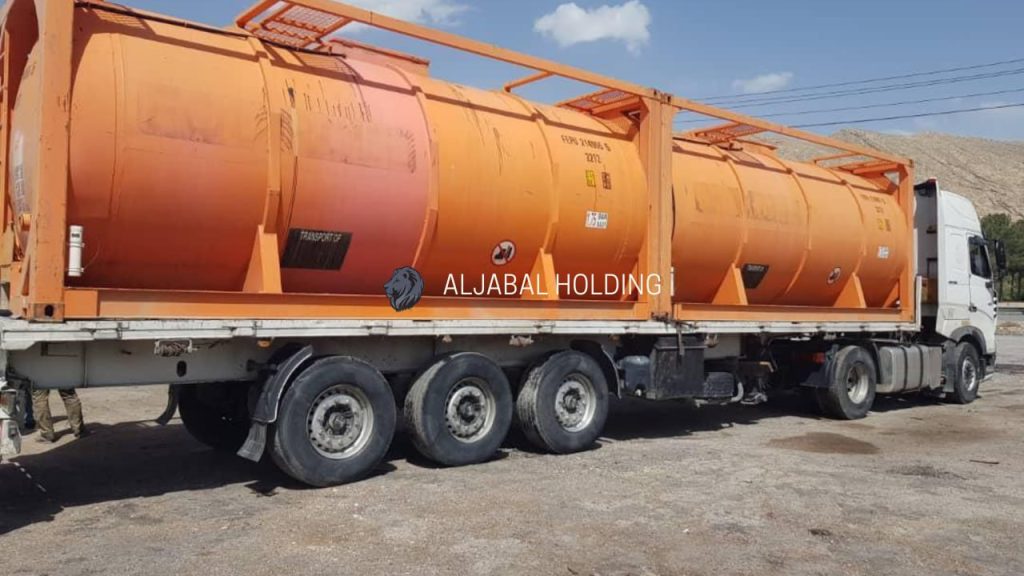

Global Supply Chain and Distribution

Aljabal Holding doesn’t just produce world-class RC base oil—they deliver it globally, fast and reliably. With logistics hubs in the Middle East, Europe, and Asia-Pacific, they maintain a highly efficient distribution network that ensures timely deliveries across continents.

Whether you’re an OEM, a lubricant blender, or a government agency procuring for fleets, Aljabal provides seamless bulk or containerized shipments, tailored to your operational scale. The company even offers just-in-time delivery options and bulk storage partnerships to support recurring orders.

Their supply chain management system ensures real-time tracking, end-to-end visibility, and proactive inventory control, allowing clients to plan with confidence.

Quality Control and Product Certification

Every drop of RC base oil from Aljabal Holding undergoes strict quality control testing. From initial refining to final packaging, the company adheres to:

- ISO 9001 (Quality Management)

- ISO 14001 (Environmental Management)

- SAE and ASTM oil testing protocols

They run multiple lab checks for:

- Viscosity

- Flashpoint

- Sulfur content

- Oxidation stability

- Additive compatibility

Each batch is traceable, certified, and backed by a Certificate of Analysis (COA)—a mark of transparency that builds trust and reliability.

Customization and Client Support

Aljabal doesn’t operate with a one-size-fits-all mentality. Clients can request custom-tailored formulations of RC base oil with specific additives, viscosity grades, or pour points to suit unique application needs.

Their team of chemists and engineers works directly with clients to co-develop blends that align with regional climates, machinery specs, and operational goals. Need technical support? They’ve got 24/7 client service, multilingual assistance, and on-site consultation options for large clients.

Applications of RC Base Oil

Automotive Lubricants

When it comes to the automotive industry, RC base oil is a staple in the production of high-performance engine oils and lubricants. The automotive sector demands oils that perform well under high heat, heavy loads, and extreme stress conditions. Thanks to its excellent oxidation resistance and high viscosity index, RC base oil is well-suited for automotive engine oils, transmission fluids, and greases.

In passenger vehicles, RC base oils help reduce wear and tear, improve fuel efficiency, and extend engine life. For high-performance vehicles and heavy-duty trucks, RC base oil ensures engines run smoothly even under extreme driving conditions—whether it’s a cross-country haul or a race-track sprint.

RC base oils are also a critical component in synthetic blends, which offer the best of both worlds: the performance of synthetic oils with the cost-effectiveness of conventional oils.

Industrial Fluids and Hydraulic Oils

RC base oils play a vital role in the production of industrial lubricants and hydraulic fluids. These fluids are essential for the smooth operation of hydraulic machinery, gears, compressors, and industrial pumps. The superior purity and thermal stability of RC base oils prevent the formation of sludge, ensuring that equipment operates efficiently for longer periods, even under high pressure.

RC base oils are typically used in high-performance hydraulic systems, lubricants for heavy-duty machinery, and gear oils, which require oils that can withstand extreme temperatures and pressure without breaking down.

The ability to maintain consistent viscosity and reduce friction is a significant advantage, reducing the wear on machine parts and lowering the need for maintenance, making it a perfect solution for industries such as construction, manufacturing, and mining.

Marine and Aviation Industry Uses

In the marine and aviation sectors, where reliability and performance are paramount, RC base oils are indispensable. These industries require lubricants that can function flawlessly even in the harshest environmental conditions—whether it’s the saltwater of the ocean or the low temperatures and high altitudes of aviation.

RC base oils are formulated into marine engine oils, turbine oils, and aviation lubricants. They offer outstanding rust protection, high shear stability, and anti-wear properties, all of which are crucial for preventing engine failure in these demanding environments.

By ensuring the safe operation of engines in both the air and sea, RC base oils help maintain the longevity of marine vessels and aircraft, ensuring safety and performance at all times.

Market Demand and Industry Trends in 2025

Rise in Synthetic and Semi-Synthetic Lubricants

The shift toward synthetic and semi-synthetic lubricants has been accelerating, and this trend is expected to continue in 2025. Synthetic oils, which are often derived from high-quality base oils like RC, offer superior performance in extreme conditions. They provide better stability, lower volatility, and improved fuel economy.

RC base oil, being an ideal foundation for these lubricants, plays a crucial role in this shift. The ability to create high-quality synthetic blends with RC base oil allows manufacturers to meet the evolving demands of consumers who seek high-performance, eco-friendly, and cost-effective lubricants.

As the automotive industry moves toward more fuel-efficient and environmentally friendly vehicles, the demand for synthetic oils and blends derived from RC base oil is expected to rise, driven by stricter emissions regulations and performance standards.

Sustainability and Eco-Friendly Base Oils

Environmental concerns continue to dominate the global agenda, and industries are under pressure to reduce their ecological footprint. Eco-friendly base oils are gaining popularity, and manufacturers are seeking ways to create lubricants that are both high-performance and biodegradable.

The use of Acid Technology in refining RC base oil already brings a level of sustainability to the table, as it reduces waste and lowers emissions. In 2025, we’re likely to see more innovation in the development of bio-based and renewable base oils, which will further align with the growing demand for green lubricants in various industries.

As sustainability becomes a key factor in purchasing decisions, RC base oil suppliers like Aljabal Holding are expected to lead the way in producing eco-conscious products without compromising on performance.

Technological Innovations Shaping the Market

2025 is also expected to see the integration of advanced technologies such as AI and IoT in lubricant monitoring and performance analysis. These innovations will allow industries to monitor the condition of their lubricants in real time, optimizing the usage and lifespan of lubricants and base oils.

In addition, improvements in refining technology, like smart refineries and automation in the production process, will further enhance the performance and consistency of RC base oils, making them even more suitable for next-generation machinery.

The combination of better data, advanced materials, and cutting-edge refining techniques will shape the future of base oil production, ensuring that products like RC base oil continue to meet the ever-changing demands of global markets.

Why Choose Aljabal Holding as Your Supplier?

Competitive Pricing and Global Reach

Choosing the right supplier for RC base oil is crucial for maintaining consistent performance and cost-efficiency. Aljabal Holding offers a competitive pricing structure without sacrificing quality. Their global supply chain ensures that businesses, regardless of their location, can easily access high-quality RC base oil and associated products.

With production facilities and distribution centers strategically placed worldwide, Aljabal guarantees timely delivery and cost savings for its customers. Whether you’re ordering in bulk or for a single project, Aljabal ensures that your supply needs are met without delay.

Proven Track Record and Testimonials

With years of industry experience and a growing list of satisfied customers, Aljabal Holding’s reputation for excellence speaks for itself. Testimonials from industry leaders highlight the company’s commitment to high-quality products, consistent performance, and exceptional customer service.

Aljabal’s client-first philosophy has earned them long-term partnerships with leading players in industries like automotive, manufacturing, and marine, ensuring their position as a trusted RC base oil supplier worldwide.

Commitment to Compliance and Regulation

Aljabal Holding is dedicated to maintaining the highest standards in the industry. They adhere to ISO, ASTM, and SAE standards, ensuring that every product is fully compliant with global regulations and quality assurance benchmarks. From environmental safety to occupational health standards, Aljabal’s commitment to regulation and compliance gives customers peace of mind.

Conclusion

Aljabal Holding stands out as a leading supplier of RC base oil enhanced with Acid Technology, providing industries around the world with high-performance base oils that meet the highest standards. Whether you’re in the automotive, industrial, or marine sector, Aljabal offers the consistency, quality, and innovation you need to keep your equipment running smoothly and efficiently.

As the demand for sustainable, high-performance lubricants grows, Aljabal Holding’s continued focus on innovation, quality control, and client satisfaction ensures that it will remain a key player in the base oil market for years to come.

FAQs

1. What makes RC base oil superior for lubrication?

RC base oil’s high oxidation resistance, thermal stability, and viscosity index make it an excellent choice for various lubrication needs. It ensures longer engine life, reduced wear, and better fuel efficiency compared to other oils.

2. Is RC base oil suitable for all industrial applications?

Yes, RC base oil is versatile and is used in a wide range of applications, including automotive, industrial machinery, hydraulic systems, and marine engines.

3. How does Aljabal Holding ensure product consistency?

Aljabal maintains strict quality control measures, running each batch of RC base oil through multiple tests and certifications to ensure it meets international standards.

4. Can I request a customized RC base oil formulation?

Yes, Aljabal offers custom formulations of RC base oil based on your specific requirements, including viscosity, additives, and more.

5. Is Aljabal Holding certified to export internationally?

Yes, Aljabal Holding holds international certifications and operates a global distribution network, ensuring timely and compliant exports worldwide.