What Is Polymer Modified Bitumen (PMB)?

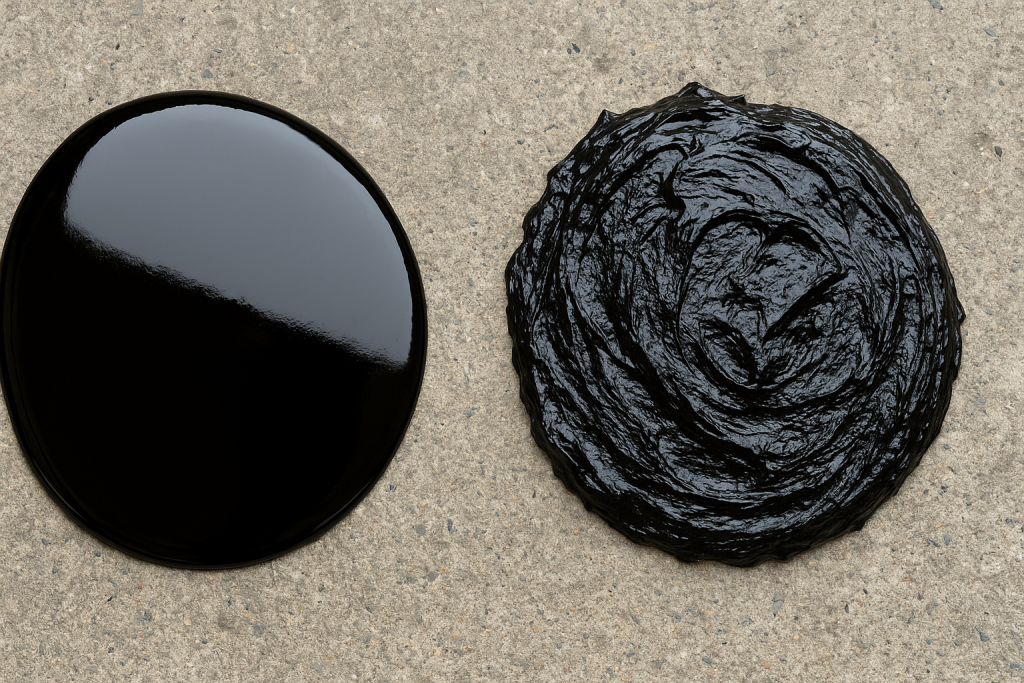

Polymer Modified Bitumen (PMB) is a superior form of bitumen enhanced with polymer additives such as Styrene-Butadiene-Styrene (SBS), Ethylene Vinyl Acetate (EVA), or crumb rubber. These additives significantly improve the physical and mechanical properties of the binder, making it more durable, elastic, and resistant to environmental stress.

Unlike conventional bitumen, PMB maintains its performance under extreme traffic loads, wide temperature variations, and harsh weather conditions, making it a preferred choice for modern infrastructure.

Why Choose PMB Over Conventional Bitumen?

1. Enhanced Durability

- Higher resistance to rutting and cracking.

- Superior fatigue life under cyclic loads.

- Reduced maintenance frequency.

2. Superior Performance in Extreme Climates

- Maintains flexibility in sub-zero temperatures.

- Resists softening and bleeding in high heat environments.

3. Longer Pavement Life

- Extends service life of roads by 40–60% compared to standard bitumen.

- Lowers lifecycle cost of road construction.

Types of Polymer Modified Bitumen

| PMB Type | Polymer Used | Key Features |

|---|---|---|

| PMB-SBS | Styrene-Butadiene-Styrene | High elasticity and fatigue resistance |

| PMB-EVA | Ethylene Vinyl Acetate | Excellent aging and oxidation resistance |

| PMB-CR | Crumb Rubber | Eco-friendly, cost-effective, improves skid resistance |

Applications of PMB in Infrastructure

1. High-Traffic Highways

PMB is extensively used in highways where heavy traffic and high axle loads demand superior performance.

2. Airport Runways

It withstands the enormous pressure of landing aircraft and resists deformation under jet fuel spills.

3. Urban Roads

Reduced noise, increased skid resistance, and longer service life are crucial for city roads.

4. Bridge Decks and Overpasses

Due to temperature swings and structural movement, PMB’s elasticity ensures structural integrity.

Specification of Polymer Modified Bitumen

| Property | Test Method | Unit | Typical Range |

|---|---|---|---|

| Penetration @ 25°C | ASTM D5 / EN 1426 | dmm | 40 – 60 |

| Softening Point (R&B) | ASTM D36 / EN 1427 | °C | ≥ 60 |

| Elastic Recovery @ 25°C | EN 13398 | % | ≥ 60 |

| Ductility @ 25°C | ASTM D113 | cm | ≥ 100 |

| Viscosity @ 135°C | ASTM D4402 | cP | 1000 – 3000 |

| Fraass Breaking Point | EN 12593 | °C | ≤ -10 |

| Storage Stability @ 163°C | EN 13399 | °C | ≤ 5 difference |

| Flash Point | ASTM D92 | °C | ≥ 230 |

| Aging Resistance (RTFOT) | ASTM D2872 | – | Meets penetration & softening criteria |

PMB vs Conventional Bitumen: A Comparative Analysis

| Property | Conventional Bitumen | Polymer Modified Bitumen |

|---|---|---|

| Temperature Susceptibility | High | Low |

| Rutting Resistance | Moderate | Excellent |

| Fatigue Resistance | Low | High |

| Elastic Recovery | Poor | Superior |

| Crack Resistance | Moderate | High |

| Service Life | 5–8 years | 10–15 year |

Environmental Advantages of PMB

- Recycling Potential: Use of recycled polymers and crumb rubber reduces plastic waste.

- Lower Carbon Emissions: Longer-lasting pavements mean reduced reconstruction frequency and fewer emissions over time.

- Improved Fuel Efficiency: Smoother, well-maintained roads improve vehicle efficiency.

Quality Standards and Compliance

Polymer Modified Bitumen must conform to stringent global standards such as:

- EN 14023: European standard for PMB specifications.

- ASTM D5976: American standard for testing elastic recovery of PMB.

- IS 15462: Indian specifications for PMB used in flexible pavements.

Storage and Handling Considerations

- Store at a temperature of 160–180°C to maintain workability.

- Use insulated tanks with continuous agitation to prevent polymer separation.

- Avoid contamination from dust or water during loading and unloading.

Challenges and Mitigation in PMB Use

| Challenge | Mitigation Strategy |

|---|---|

| High Initial Cost | Offset by longer life and reduced maintenance |

| Storage Stability | Use of high-shear mixers and storage tanks with stirrers |

| Polymer Separation | Selection of compatible polymers and proper blending techniques |

Conclusion: PMB as a Game-Changer in Pavement Technology

At Aljabal Holding, we believe that Polymer Modified Bitumen is not just an improvement—it’s a necessity for modern, sustainable, and high-performance infrastructure. With superior mechanical properties, extended service life, and reduced lifecycle costs, PMB stands as the future of road construction.

Whether you’re constructing national highways, airport runways, or urban expressways, PMB delivers unmatched performance and long-term value. Our premium-grade PMB products comply with international standards and are tailored for varying climatic and traffic conditions.

Contact Us for inquiries

Looking for a reliable PMB supplier for your next infrastructure project? Aljabal Holding offer customized PMB blends to suit your performance and environmental requirements. Get in touch with our technical experts today.

Address:

Office 1210, Floor 12, Grosvenor Business Tower, Barsha Heights Dubai, UAE

Office Tel / fax :

+971 455 4329

WhatsApp and direct mobile:

+971523717966

Youtube Channel:

https://www.youtube.com/channel/UCD5KQYPL9snHIpdtMoURD1w

Email:

info@aljabalglobal.com