Introduction

Road construction is one of the most critical infrastructure projects in any country. The quality of roads directly affects transportation, logistics, and economic growth. Among the materials used for road surfacing, bitumen has remained a traditional choice for decades. However, with technological advancements, Polymer Modified Bitumen (PMB) has emerged as a superior alternative in many cases. This article explores the key differences, advantages, and disadvantages of bitumen versus PMB to help you understand which material is better for roads.

What is Bitumen?

Definition and Composition

Bitumen is a viscous, black, and sticky substance derived from crude oil during the refining process. It is a byproduct that consists mainly of hydrocarbons and is used primarily as a binder in asphalt for road construction.

Common Uses of Bitumen

Bitumen is commonly used in:

- Asphalt concrete for road pavements.

- Waterproofing materials.

- Roofing applications.

- Protective coatings.

What is Polymer Modified Bitumen (PMB)?

Definition and Chemical Structure

Polymer Modified Bitumen is a form of bitumen enhanced with polymers such as Styrene-Butadiene-Styrene (SBS) or Ethylene Vinyl Acetate (EVA). These additives improve the performance of the base bitumen, making it more flexible and durable.

Why Use PMB?

PMB is designed to address the limitations of conventional bitumen, particularly its susceptibility to temperature changes, rutting, and cracking under heavy loads.

Key Differences Between Bitumen and PMB

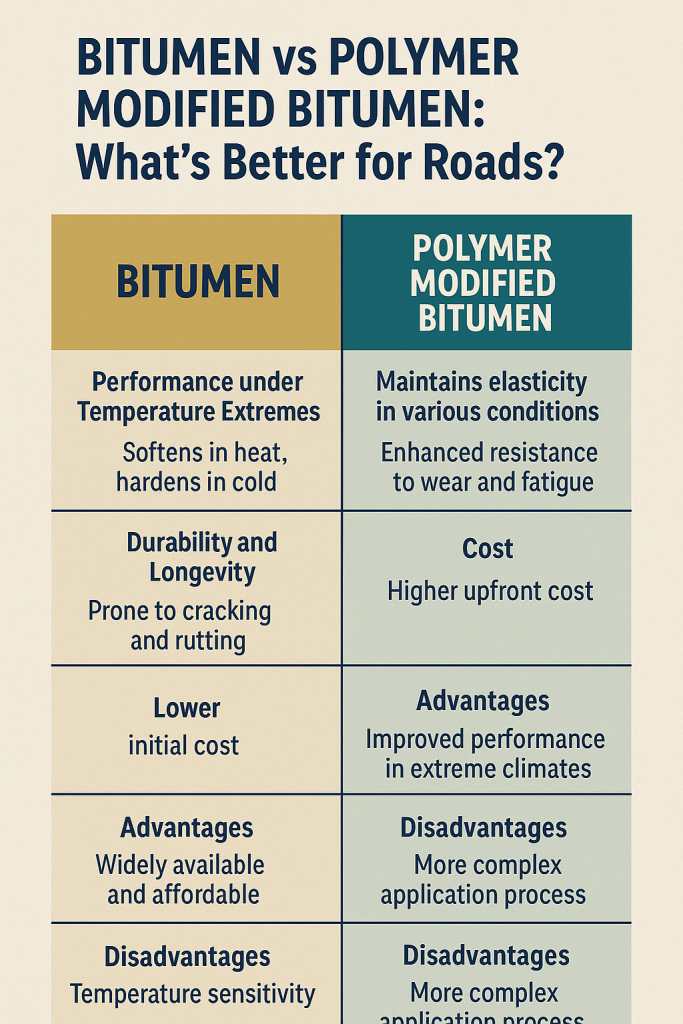

Performance under Temperature Extremes

- Bitumen tends to soften in extreme heat and harden in cold conditions, leading to cracks and potholes.

- PMB, on the other hand, maintains elasticity and structural integrity in varying weather conditions.

Durability and Longevity

PMB roads can last 50% longer than those made with conventional bitumen, reducing the frequency of maintenance and repairs.

Cost Considerations

While PMB is more expensive upfront due to the added polymers and specialized processing, it often results in lower life cycle costs due to its reduced maintenance requirements.

Advantages of Conventional Bitumen

Availability and Affordability

Bitumen is widely available and cost-effective, making it the go-to material for many standard road projects.

Ease of Application

Bitumen requires less specialized equipment and expertise during application compared to PMB.

Disadvantages of Conventional Bitumen

Temperature Sensitivity

Bitumen is vulnerable to cracking in cold weather and softening in hot climates, which can lead to early road failures.

Susceptibility to Cracking and Rutting

Heavy traffic loads can cause rutting (wheel-track depressions) and cracks on bitumen surfaces over time.

Advantages of Polymer Modified Bitumen

Enhanced Durability

The polymer additives make PMB more resilient to traffic loads and weather fluctuations.

Improved Resistance to Rutting and Fatigue

PMB is particularly beneficial for highways, airports, and heavy-duty roads due to its superior resistance to deformation.

Weather Adaptability

PMB performs exceptionally well under both hot and cold weather conditions.

Disadvantages of PMB

Higher Cost

PMB can cost 20-50% more than conventional bitumen due to polymer additives and specialized production.

Complexity in Application

Laying PMB requires trained personnel and specialized equipment to achieve optimal results.

When to Use Bitumen vs PMB

For Standard Roads and Urban Areas

Bitumen is sufficient for roads with moderate traffic and less extreme weather conditions.

For High-Traffic Highways and Airports

PMB is the preferred choice due to its superior performance under heavy loads and harsh conditions.

Life Cycle Cost Analysis

Initial Cost vs Maintenance Cost

Although PMB’s initial cost is higher, its reduced need for maintenance and longer lifespan can make it more economical over time.

Long-Term Performance

PMB roads can withstand heavy usage without major repairs for up to 10-15 years, compared to 5-7 years for conventional bitumen.

Environmental Impact

Recyclability

Both bitumen and PMB are recyclable, but PMB’s advanced processing can sometimes make recycling slightly more complex.

Energy Consumption during Production

PMB production requires more energy due to the addition of polymers, but its extended life reduces the environmental footprint over time.

Global Trends in Road Construction

Countries Moving Towards PMB

Developed nations like the USA, Japan, and Australia are increasingly adopting PMB for highways and airport runways.

Innovative Blends of Bitumen

Research is ongoing to create hybrid blends of bitumen and PMB to balance cost and performance.

Expert Opinions and Case Studies

Performance of PMB in Harsh Climates

Studies have shown PMB roads perform better in tropical and freezing climates compared to conventional bitumen.

Urban vs Rural Applications

PMB is more commonly used in urban settings with high traffic density, while bitumen remains the norm in rural areas.

Future of Road Surfacing Materials

Emerging Technologies

Nanotechnology and bio-based polymers are being explored to improve the performance of PMB.

Sustainable Alternatives

Eco-friendly additives and warm-mix technologies are becoming popular for reducing the carbon footprint of road construction.

Conclusion

When it comes to Bitumen vs Polymer Modified Bitumen, the right choice depends on your project requirements. For standard roads with lighter traffic, bitumen offers a cost-effective solution. However, for high-traffic highways, airports, or regions with extreme weather conditions, PMB delivers unmatched performance and durability, justifying its higher cost. The future of road construction lies in a blend of innovation, sustainability, and cost-efficiency, where PMB is likely to play a leading role.

FAQs

1. What is the main difference between bitumen and PMB?

PMB includes polymer additives that enhance flexibility, durability, and temperature resistance, unlike conventional bitumen.

2. Is PMB worth the extra cost?

Yes, for high-traffic and extreme weather conditions, PMB’s longer lifespan and reduced maintenance costs make it worth the investment.

3. Which roads benefit most from PMB?

Highways, airports, and heavy-duty urban roads benefit the most due to PMB’s superior resistance to rutting and cracking.

4. Can PMB be recycled like conventional bitumen?

Yes, but the recycling process can be slightly more complex due to the polymer content.

5. Which countries are leading in PMB adoption?

The USA, Australia, Japan, and several European countries are leading the way in adopting PMB for infrastructure projects.